Resources

Treatment of high concentrated organic wastewater

One case: Paracetamol production of refined liquor resource recycling

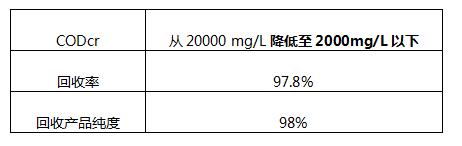

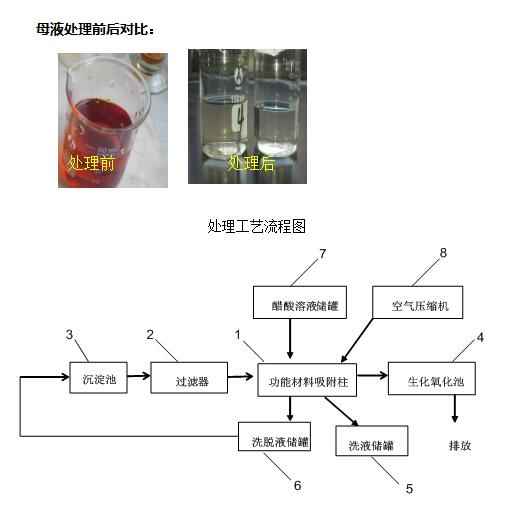

Jiangsu, a pharmaceutical factory production of acetaminophen products containing acetaminophen on mother liquor wastewater, about 1.7% have peculiar smell, every day about 60 tons of raw water CODcr near 20000mg/L. The original method is three effect evaporation of recycling materials, after process improvement with functional polymer materials instead of three effect evaporation, eluent production function material apply, functional materials can be used repeatedly after desorption. So that the cost of each ton of paracetamol products to reduce the cost of 500 yuan, played a waste water treatment, energy saving, consumption, reduce costs, such as the role of the four, the company was therefore the local economic and Trade Commission of the $100 thousand reward. At present, the manufacturer has been used for four years.

Case two: wastewater treatment and utilization of benzene two amine

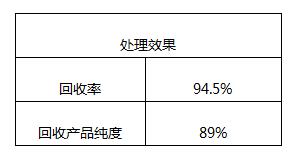

The production of benzene two amine wastewater in a factory, the content of benzene is, the content of benzene is, the pH is 9-10, and has the peculiar smell. After the adsorption treatment of the functional polymer material, the content of benzene is recovered to 89%, and the comprehensive recovery rate is about 94.5%.